Hard hats also named helmets used in workplace environments such as industrial or construction sites to protect the head from injury due to falling objects, impact with other objects, debris, rain, and electric shock. Suspension bands inside the helmet spread the helmet's weight and the force of any impact over the top of the head. A suspension also provides space of approximately 30 mm (1.2 inches) between the helmet's shell and the wearer's head, so that if an object strikes the shell, the impact is less likely to be transmitted directly to the skull. Some helmet shells have a mid-line reinforcement ridge to improve impact resistance. The rock climbing helmet fulfills a very similar role in a different context and has a very similar design.

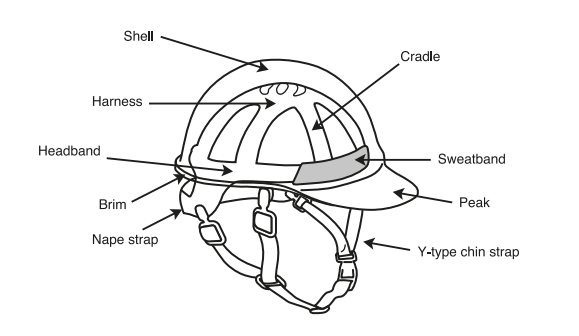

The hard hat is made up of three parts: Cap shell, Cap lining, and a lower band.

(1) Cap shell: This is the main component of the hard hat, generally using an oval or hemispherical thin-shell structure. This structure, under the impact pressure, will produce a certain degree of pressure deformation, due to the rigid properties of the material absorption and dispersion of force, coupled with the smooth surface and circular curve sway the impact and reduce the impact time.

(2) Cap lining: The cap lining is the total name of the cap shell directly in contact with the top of the wearer's head, which consists of a cap hoop ring strap, a top strap, a strap, a brace, a sweat-absorbing belt, a cushioning technique rope, etc.

The material of the cap lining is cotton ribbon, synthetic fiber belt, and plastic lining, the cap hoop is a ring belt, tightly around the person's head when worn, with the front part of the suction material, has a specific effect of sweat absorption. The cap hoop ring belt can be divided into two types fixed belt and adjustable belt, the cap hoop has the rear neck hoop and no rear neck hoop.

(3)The band: The strap attached to the lower armpit, the role of the fixed hard hat, the smaller group consists of a belt and a locking card. No cap lining with back neck hoops, with a "y" sideband.

A safety helmet protects the top of the head from flying objects, striking against objects, and being struck by objects by absorbing energy.

(a) Partial destruction or damage of the shell;

(b) Stretching of the harness

(c) Crushing of the protective padding.

The residual force of the impact is spread over the surface of the head, thus lessening the injury chance. Stringent performance test requirements apply to safety helmets.

(1)White

Site managers, supervisors, engineers, or supervisors usually wear white hats on site.

(2)Yellow

Yellow is the color for general laborers and earth-moving operators.

(3)Blue

Carpenters and other technical operators, including electricians, will generally wear blue hard hats, while road crews wear orange.

(4)Green

Green often signifies a safety inspector but can also be used by new workers on the site or probationary staff.

(5)Orange

Lifting operatives, slingers, or traffic marshals but mainly lifting activists wear orange hard hats so the crane operator can pick them out from other operatives.

(6)Red

Fire Marshal's usually wear red hard hats complete with stickers ("Fire Marshal").

(7)Brown

Brown hats are worn by welders and other workers with high heat applications.

(8)Grey

Grey is the color often worn by site visitors.

(1)Hard hat impact protection is divided into two categories: Type I and Type II.

Type I hard hats are intended to reduce the force of impact resulting from a blow only to the top of the head. This form of effect may result from a hammer or nail gun falling from above.

Type II hard hats are intended to reduce the force of lateral impact resulting from a blow that may be received off-center, from the side, or to the top of the head. This form of influence may result from contact with the sharp corner of a side beam.

(2)Electrical Classes

According to ANSI/ISEA Z89.1-2009 standards, hard hat electrical performance is divided into three categories: Class E, Electrical, Class G, General, and; Class C, Conductive.

Class E (Electrical) Hard Hats are designed to reduce exposure to high voltage conductors and offer dielectric protection up to 20,000 volts (phase to ground). This amount of voltage protection, however, is designated to the head only and is not an indication of voltage protection allocated to the user as a whole.

Class G (General) Hard Hats are designed to reduce exposure to low voltage conductors and offer dielectric protection up to 2,200 volts (phase to ground). As is the case with Class E hard hats, this amount of voltage protection is designated to the head only and does not account for voltage protection allocated to the user as a whole.

Class C (Conductive) Hard Hats differ from their counterparts in that they are not intended to protect against contact with electrical conductors. On the contrary, Class C hard hats may include vented options, which not only protect the wearer from the impact but also provide increased breathability through their conductive material (such as aluminum) or added ventilation.

Hard hat materials are glass steel, polycarbonate plastic, ABS plastic, ultra-high molecular polyethylene plastic, modified polypropylene plastic, paper glue, bamboo, and other materials.

(1) Glass and hard steel hat: mainly used in metallurgical high-temperature work sites, oil field drilling, deforestation, power supply lines, high-rise construction, and cold area construction scenes.

(2) Polycarbonate plastic hard hat: mainly used in oil field drilling, forest harvesting, power supply lines, construction, and other operations.

(3) ABS plastic hard hat: mainly used in mining, machinery industry, and other high impact strength of indoor room temperature workplace.

(4) Ultra-high molecular polyethylene plastic helmet: a wide range of applications, such as metallurgical chemicals, mines, construction, machinery, electricity, transportation, forestry, and geological and other types of work.

(5) Modified polypropylene plastic helmet: mainly used in metallurgy, construction, forest, electricity, mining, wells, transportation, and other jobs.

(6) Rubber miners' hard hats: mainly used in coal mines, underground, tunnels, culverts, and other places of operation. When wearing, do not have a jaw strap.

(7) Plastic miner hard hat: product performance in addition to high-temperature resistance is higher than the rubber miner's cap, another concert, and rubber miners hat is the same.

(8) Cold-proof hard hat: suitable for operations in cold areas in winter fields and open-air sites, such as mining, geological drilling, forestry logging, construction, and port handling.

(9) Paper glue hard hat: suitable for outdoor operations, the role of anti-solar radiation, wind and sand, and rain.

(10) Bamboo hard hats: mainly used in metallurgy, construction, forestry, mining, docks, transportation, and other operations.

(11) Other woven hard hats: suitable for hot areas without open firework.

Before you go!

As one of the biggest Personal Protective Equipment (PPE) manufacturers and exporters in China, T-safety enjoys an excellent business relationship with our customers around the world, during the past 20 years, we are dedicated to providing quality products at reasonable prices and professional trading services.

T-safety provides a wide range of PPE products such as safety helmets, safety glasses, ear muffs, respirators, welding masks, gloves, knee pads, shoes, uniforms, traffic cones, etc. We use the latest technology and most up-to-date machinery to produce products and our products can meet international standards and get many international certificates. Besides, we set up an R&D department, production department, sales department, quality control department, and operation department to offer professional services to our customers.

With the outstanding quality products and perfect after-sales services, we win the praise of customers worldwide. We are looking forward to cooperating with you in the near future.

Copyright © Hebei Sinotools Industrial Co.,Ltd. All Rights Reserved | Powered by  Sitemap

Sitemap