Welders have many dangers at work every day. Burns, eye damage, and cuts can happen fast if you do not wear the right protection. The correct welding safety ppe keeps workers safe from bad injuries.

All welders should check their gear often and always put safety first.

-Always put on the correct personal protective equipment (PPE) to stop injuries like burns and eye harm.

-Look at your PPE before every shift to make sure it works well and fits you right.

-Follow a full PPE checklist to be sure you have all the safety gear you need for welding.

Welders have many dangers at work. They need personal protective equipment to stay safe. OSHA and other safety groups say welders must use certain welding ppe. Each piece of gear helps protect against different dangers in welding.

Category | Description |

|---|---|

Head Protection | Protects the head from falling objects and other dangers. |

Hearing Protection | Shields ears from loud noises during welding. |

Eye and Face Protection | Guards eyes and face against UV and IR radiation, sparks, and flying debris. |

Respiratory Protection | Prevents inhalation of harmful fumes and gases. |

Protective Clothing | Blocks sparks, slag, and heat with fire-retardant materials. |

Foot Protection | Keeps feet safe from falling objects and hot materials. |

Hand Protection | Defends hands from burns and cuts during welding. |

Welders should wear these items: a protective helmet, goggles, ear protection, flame-resistant clothing, gloves, boots, respirators, and fire extinguishers.

Different welding jobs need different welding ppe. MIG and TIG welding make less heat and spatter, so workers can use lighter gloves and clothes. Stick welding makes more heat and spatter, so workers need thicker gloves and heavy clothes. If welding in a small space, workers may need a full-face respirator and extra layers.

Welding helmets keep out UV and IR rays, sparks, and flying bits. Gloves come in special types for MIG, TIG, and Stick welding. Flame-resistant jackets and pants protect the body from heat and sparks. Safety boots with steel toes keep feet safe from heavy or hot things.

Welding can be very dangerous. If workers do not use welding safety ppe, they can get hurt or sick.

Welders often get sick or hurt from their job. They can get lung disease, eye and skin injuries, asphyxiation, breathing problems, and metal fume fever, which feels like the flu.

More than 91% of welders get eye injuries each year. Over 83% get skin burns. Many also feel burning in their eyes or have trouble breathing. These facts show why welders must use personal protective equipment and follow safety rules.

Welding ppe keeps workers safe from these dangers. Respirators help filter out bad fumes and gases. Helmets and goggles protect eyes from bright light and flying bits. Flame-resistant clothes stop sparks and heat. Gloves and boots keep hands and feet safe from burns and cuts.

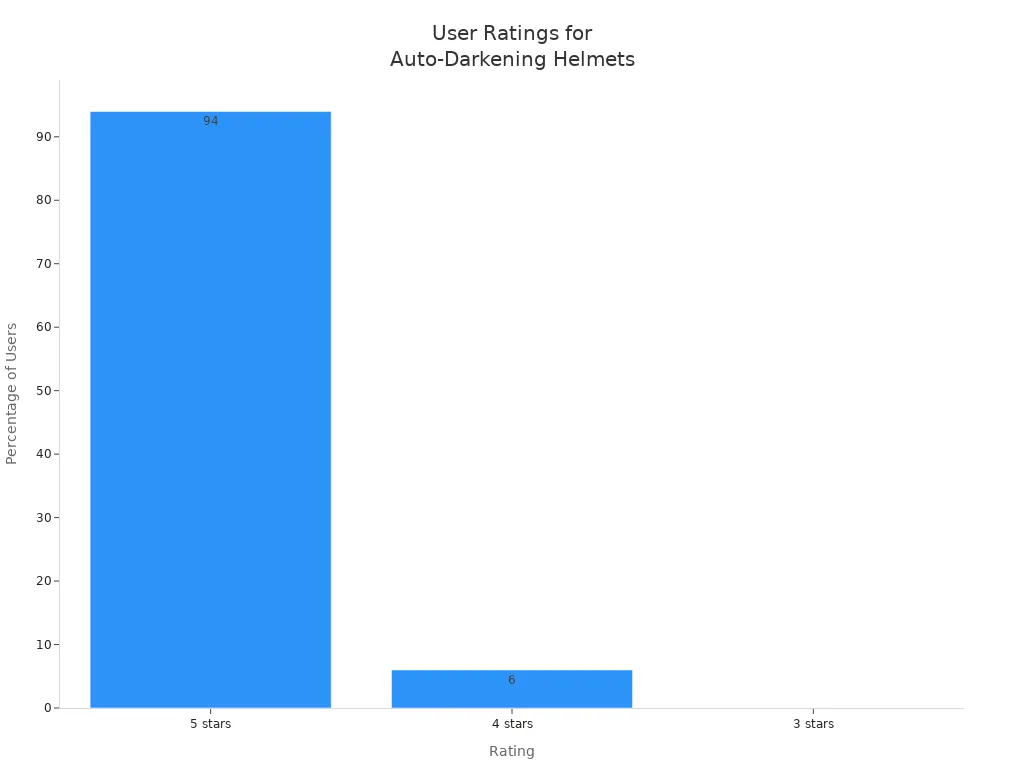

A welding helmet keeps your head and face safe. It blocks dangerous rays and flying pieces. The helmet shell stops ultraviolet and infrared rays. These rays can hurt your eyes badly. Welders need a helmet with the right filter shade. This keeps their eyes safe from bright lights. Many helmets have passive lenses with a fixed shade. The shade is often number 10 and made from special glass. These lenses soak up bad rays and help you see clearly. Some helmets have auto-darkening filters. These filters change shade fast when welding starts. This helps welders see better and work quicker. Studies show True Color helmets help welders finish jobs 30% faster. Most people like auto-darkening welding helmets for comfort and better vision.

Feature | Description |

|---|---|

Helmet Shell | Protects from UV & IR radiation and flying debris |

Filter | Certified safety filter meets CE and ANSI Z 136.1 standards |

Protection Level | 1000 – 1100 (OD8+) D LB7 + IR LB8 CE |

Shade | 3 |

Standards | Meets EN ISO 16321, EN 207, ANSI Z87 |

Welding helmets must meet safety rules like ANSI/ISEA Z87.1 in the USA. In Europe, they must meet EN 175. These rules make sure helmets are strong and clear. They also protect from harmful rays.

A face shield gives more safety for your face. It protects from hot sparks and flying metal. Welders use welding face shields to follow OSHA rules and stop injuries. Fire-resistant caps and neck gaiters protect your scalp and neck. They block heat and sparks. These items use flame-resistant cotton to stop burns. They keep your skin safe. Welders should pick caps and gaiters that fit well. They should cover all skin that could get burned.

Welders must wear jackets to stop burns and sparks. These jackets use special materials that do not burn fast. Some jackets are made from thick cowhide leather. Others use flame-resistant cotton. Both materials help stop burns and injuries. Flame-resistant jackets protect better than normal work shirts. Studies show these jackets lower burn injuries by over 80% at work. Workers in flame-resistant clothes are safer in flash fires. These jackets also help workers heal faster if they get burned.

• Flame-resistant materials do not catch fire easily.

• Cowhide leather and flame-resistant cotton are popular choices.

• Jackets come in styles like khaki FR cloth and thick leather.

Pants and aprons keep your legs safe from hot metal and sparks. Welders should wear clothes that cover their legs, arms, and neck. The fabric must be strong and not burn easily. It should last through many washes. Good designs let welders move without trouble. Safety features include pockets with covers and smooth buttons. These stop metal splashes from getting trapped. Welders often wear flame-resistant aprons for extra safety during risky jobs.

Clothes that fit right keep welders safe and comfy. Good fit means welders can move without feeling stuck. They can work longer and not get tired fast. Jackets and pants that fit well help stop accidents. Flame-resistant cotton and leather give safety and comfort. Welders should check that their clothes fit close but are not too tight.

Welders can hurt their hands in many ways. The right welding gloves help stop burns, cuts, and bumps. Leather welding gloves block heat and keep sparks away. They also protect from sharp things. Cotton inside the gloves makes them soft and easy to wear. This helps welders move their fingers better. Gloves should fit well and help you hold tools.

The best gloves depend on the welding job. TIG welding needs thin, soft gloves for better control. These are made from goatskin or deerskin. MIG welding uses thicker gloves from cowhide or pigskin. These give more heat safety. Stick welding needs the thickest gloves with long cuffs. These protect from high heat and flying sparks.

• TIG Welding Gloves: Thin and bendy for careful work.

• MIG Welding Gloves: Thicker to stop heat and sparks.

• Stick Welding Gloves: Thickest and longest for top safety.

Welders' arms can get hurt by sparks, heat, and sharp metal. Arm guards and sleeves help stop burns and cuts. These sleeves also protect skin from scrapes. Safety experts say many work injuries happen to arms. Wearing arm guards and sleeves lowers the risk of getting hurt. They help welders stay safe at work.

Welding makes fumes that can hurt your health. Good airflow keeps the air clean. Local exhaust ventilation (LEV) pulls fumes away from your face. In small rooms, change the air at least ten times each hour. Big work areas need four air changes every hour. Welding booths trap fumes and help remove them. New booths have special filters to clean the air better.

• LEV systems catch and take away bad stuff right where it starts.

• Welding booths can be made to fit and have filters added.

Fires can happen easily in welding places. Sparks, hot metal, and things that burn can start fires. Workers should move things that can catch fire away before welding. Keep flammable stuff at least 35 feet from the work spot. If you cannot move something, cover it with flame-resistant material. Always have a fire extinguisher close by. A fire watch helps find and stop fires quickly.

1. Move things that burn away from welding spots.

2. Use covers for items that cannot be moved.

3. Keep a fire extinguisher nearby.

4. Have someone watch for fires while welding.

Respirators and masks help welders breathe clean air. These items filter out bad fumes. They keep your lungs safe while you weld.

Welders need to check their PPE before each shift. Looking at gear often helps find problems early. This keeps workers safe from getting hurt.

Normal clothes cannot stop sparks or heat. Flame-resistant gear blocks burns. It keeps welders safe while they work.

Copyright © Hebei Sinotools Industrial Co.,Ltd. All Rights Reserved | Powered by  Sitemap

Sitemap